SAY NO TO SINGLE PLANE BALANCING!!

WE ONLY DUAL PLANE BALANCE ALL OF OUR TURBOS.

The most critical thing you can do for your turbo is to have it Dual Plane balanced.

Imagine going in to get your rear tires balanced on your car and since the cars are connected by a common rear shaft, the tire shop only balances one tire to get the rotating assembly in balance. That is single plane balancing.

The idea behind SINGLE PLANE balancing is that since they are connected by ONE SHAFT that they spin the whole unit and balance it so it spins and is in balance as one unit. Imagine the massive vibration you would get if the opposing tire was severely out of balance BUT the weights to correct it are put on the other tire.

Single plane balancing is used by many suppliers because its fast, it does not require high dollar equipment or trained technicians to operate the balancer and/or interpret the data.

Single plane balancing is the single most cause of pre-mature bearing and turbo seal failure in rebuilt turbochargers. In other words… if your selected shop single plane balances and one side has a weight issue, their balancer can’t pick it up and that turbo will almost certainly fail and you will be doing the job again, sooner than you think.

“What is DUAL PLANE BALANCING”

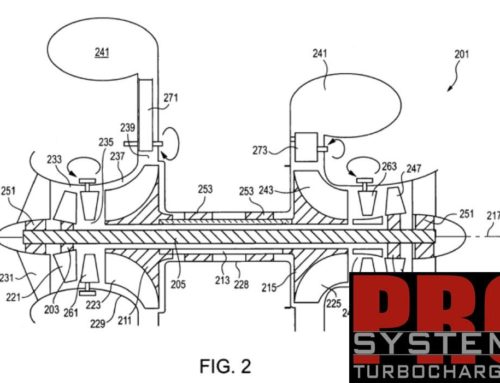

Dual plane balancing Is simply balancing EACH SIDE of the turbo, meaning we balance both the turbine wheel side (exhaust side) and the Compressor Wheel side (intake side) independently, NOT as one unit like is done in SINGLE PLANE BALANCING.

Just like balancing each tire on your car independently. Our system ensures smooth operation, long turbo seal life, turbo bearing life and even faster spooling up of the turbo.